High-performance Rare Earth Magnet recycling

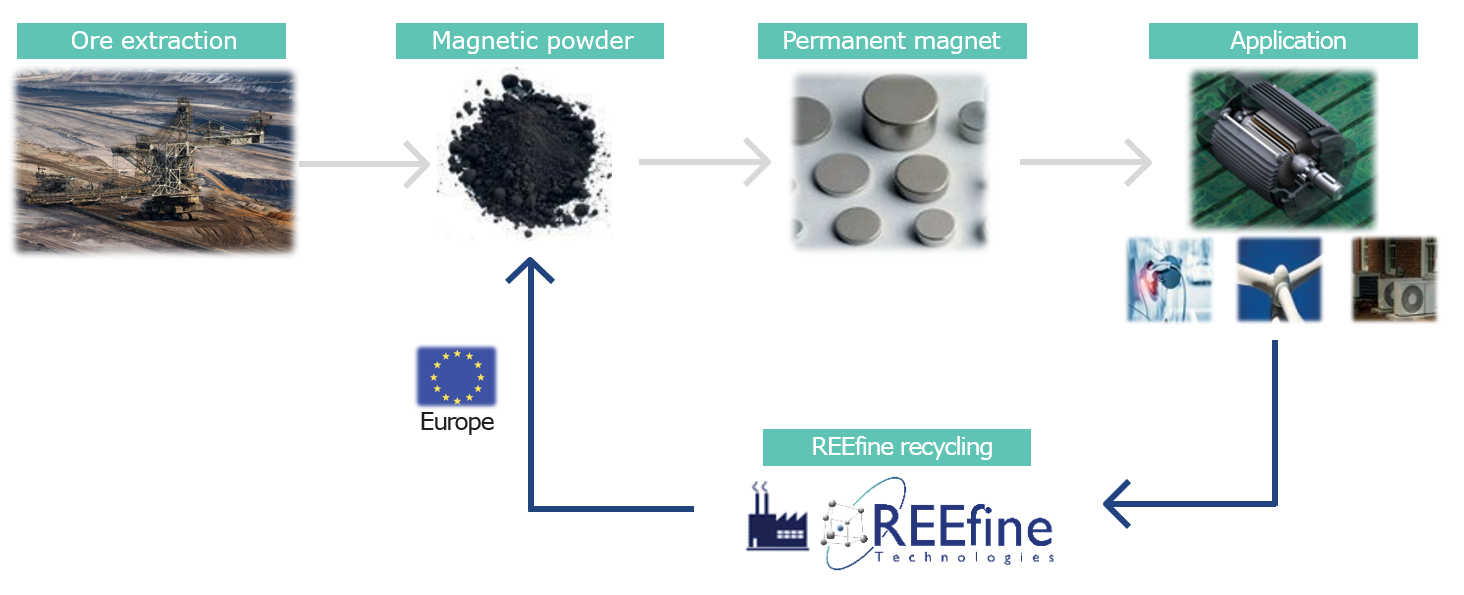

Rare Earth magnets are key materials in the energy transition of our economy (mobility, energy production, electronics…).

High growth demand on those applications are strengthening the critical issues of the existing supply chain :

Rare Earth materials supply tensions worldwide

Rare Earth elements mining and purification industries pollution

No recycling solutions in Europe

Working toward the Europe’s 2050 neutrality goal requires a sharp increase of supply in Rare Earth magnets and trade diversification will not suffice. Without alternative supply through recycling, our ambition is at risk.

About us

REEfine technologies is a french company specialised in development and production of Rare Earth (RE) magnetic materials based on neodymium iron boron (NdFeB). Our innovative process is used to extract and transform RE magnets from electrical products into high performance materials used in Rare Earth magnet production.

Our partnerships with industrial leaders in their domains and scientific experts support our industrial development to offer high quality products. REEfine-technologies joined the PerMaReco consortium (Permanent Magnet Recovery) with industrial partners PORAL, ARELEC and ECM to develop a recycling pilot plant that produces new permanent magnets at commercial scale.

We are engaged in the innovation to deploy a promising cleaner production process and supply chain that drastically lower environmental impacts of Rare Earth magnet products, especially for Europe.

REEfine technologies have established its recyling facility at Grenoble in France. Our aim is to develop a short loop recycling supply chain and develop regional circular economy of magnet supply for automotive, energy and electronics industries.

A magnetic material company with deep level of innovation and industrial knowledges

Technology capable for magnet recycling with high footprint reduction compare to mining supply

Primary ressources are highly critical for environmental and geopolitical reasons

To produce permament magnets, there is more than 10 processing steps in order to transform extracted ore to purified rare earth metals ready for permanent magnet production, with 4 different industrial facilities: mining & benefication; hydrometallurgy; oxyde separation; oxyde to metal.

All physical and chemical steps consume tremendous energy for heating and lots of chemicals that are complex to manage for hazardous reasons. The ground pollution induced is one of the worst of all types of mining activity.

The support of Rare Earth metals growth demand and thus also the neutrality goal require to double the supply. But, the market balance for those metals have already reached a deficit which is encouraging new mining and purification industrial projects.

Short loop recycling innovation

Institutional and industrial partners