Metals are critical resources for our economy and have almost indefinite recycling potential

We offer collecting solutions for recyclers and equipment end-users

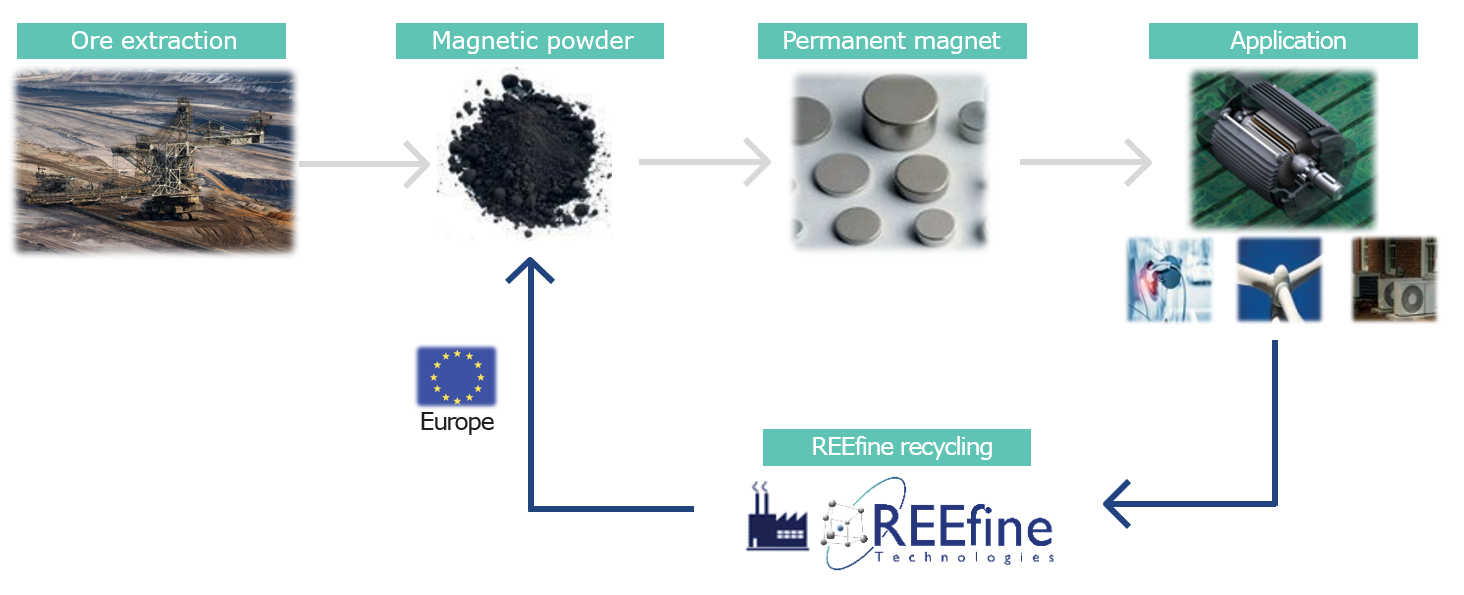

A great majority of Rare Earth magnet components in electronics and automotive are shredded. This induces shredding difficulties and magnetic characteristics losses of permanent magnets that mostly end up in low value ferrous scrap reprocessing.

REEfine-technologies identifies and organizes the collection of end-of-life equipments to maximize valorisation of materials through secondary raw materials. We are involved in pre-consumer and post-consumer waste streams of components from:

- Automotive sector

- Electronics and electrics sector

We developp partnerships with operationnal and logistics partners to implement waste treatment specialized resources at critical steps. Our aim is to contribute to the development of a new network with industrials and organsimes at regionnal sizes to secure and valorise these local resources.

Maximizing valorisation of wide range permanent magnet applications with a flexible process to best fit supply demand

Today, the estimated amount of recycling is less than 1%.

The industrial limit for higher recovery is mainly the amount of manual operations

for extraction of Rare Earth magnet from their components.

Our new approach for selective separation through dismantling and physical separation valorizes permanent magnet components at maximum rates regarding functionnal caracteristics of permanent magnets and process yield. Our innovative technology is set to produce pure rare earth alloy as magnetic powders ready to remanufacture in wide range of magnet production processes.

Sustainable supply for magnet industry

80% CO2 footprint reduction

Green technology using H2 without liquid agents

Short loop recycling innovation